Anyone who can read, comprehend and follow instructions can reload without any special skills.

However, you must follow some reloading safety rules to keep safe. You can avoid risks by following some basic safety rules.

This way, you can prevent accidents in the reloading room or shooting range catastrophe.

Not strictly following safety rules can damage your property and result in serious personal injury.

It’s always better to carefully read and understand the manufacturers user instruction before ammo reloading sessions. So, let’s quickly discuss some basic rules of safety during reloading Ammo.

You must remember to always put on safety glasses with side shields, and an apron while reloading ammo to prevent accidental primer explosion. Herein, you can use prescription safety glasses or standard approved safety glasses.

They all serve the same purpose. You should always wear safety glasses when loading primers into casings. Also make sure to you also offer safety glasses to any visitor permitted in the room with you.

You should only reload when you are fully attentive without any form of distraction. Never be in haste, give it enough time and don’t try to rush things over. Eliminate such distractions like television, visitors, or anything that could distract you. No pets, no pools and no kibitzers should be allowed.

It is forbidden to load when you are under the influence of alcohol or medicines that jeopardizes your sound judgment or concentration.

Put all components and gears in their proper place. Quickly clean up spills. Only keep the elements you require immediately on the bench. It is a good practice to clean the counter before reloading. Try to a canister of powder and type of primer on the desk at any given time.

Tag leftover containers or old plastic bullet boxes for additional primers to avoid accidental mixture of components. Ensure all powder and primers are in their unique company containers. Discard components that you can no longer determine their identification label.

If there is any need to remove the part from the manufacturer’s containers when you reload, ensure you return them to their original container after you finish. Put a “sticky-note” on the powder measurement to classify the fuel you are using.

Take the sticky note off when you return to the original container. One container of explosives should be on your bench at any given time and store the rest away to avoid costly mistakes.

You should never keep powder and primers away from heat sources, naked fire, and electrical power. Also, you must keep it away from children. Needless to say, you must avoid smoking in the reload area by all means.

Be extra careful when handling canister tubes, it can explode if you accidentally drop it. Avoid storing primers in primer tubes between one load session and the other.

Verify every month for residue build-up within the tubes and if you find any use a narrow brush and wash it in water and dry it properly before using again.

Avoid oil application on any primer tube to avoid residue build-up. On no account should you fill tubes with excessive pressure! If you discover any odd energy, instantly stop loading and fix the issue before you proceed.

The metallic lead element under excessive exposure can result in congenital disabilities, reproductive issue, or other severe medical issues.

Most primers and bullet contain lead, and you can gain lead exposure by using reload components or gears. Follow the rules below to limit your lead exposure:

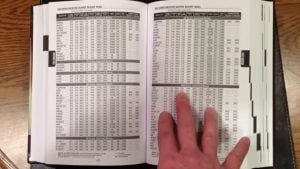

Ensure you carefully read and follow reload data published by a reputable component manufacturer..

Avoid beginning with a maximum load. Check that your reloading manual is open to the appropriate page for the cartridge you want to reload.

Being entirely sure about the load data you use is significant. When you use the wrong components or quantities, you could accidentally explode your gun and your face. You can avoid this through carefully selecting load according to your ammo capacity and cross-referencing.

Start with the base-level load and move bit by bit towards the maximum load and ensure you test after each stage. This keeps you safe in the event of any unidentified component modification.

Ensure you utilize the most up-to-date data for your cartridge. This makes your loads mirror present technology and standards.

If you are a novice with regards to reloading, always begin with moderate loads till your experience improves.

Avoid mixing up explosives; it is hazardous.

There are two forms of powder verification procedure you can use. These are automated and visual check. The automated test comes in different ways. You can only rely on the visual inspection if the case filled more than half.

Such practice can lead to spill over during incidence of a double charge. Also, apart from utilizing a powder verification procedure, read the reloading gear guide and ensure you carefully follow the recommended practices.

Use sticky tags for all components to avoid confusion. You may want to use a log book to help you quickly identify the load data for every cartridge.

Ensure you securely fasten all equipment to the work plan during use. Allowing a serious loading press to fall on your foot can result in severe injury.

If you are beginner, then be methodical in your setup & go slowly to learn the sounds and feel of the press. Every position of the handle has a corresponding resistance. Learn that. Then if anything feels different, Stop! And figure out why before proceeding..

Do not use clamps to attach heavy pieces of equipment to the bench. Follow the instruction of the manufacturer of the material for secure fastening.

Use ammo reloads carefully and sensibly. A lot of firearms producers prohibit ammo reload use on their products. They could terminate your product’s warranty when you do it against the manufacturers use instruction.

Be aware that using wrong cartridge and primer can result in serious personal injury and potentially harm people around you. It can also make the ammo unreliable during an emergency.

Using reload ammo daily is a cost-effective way to manage your ammo budget. However, you must do this carefully and safely.

Joseph Fox writes on a variety of topics ranging from reloading ammunition to gun cleaning. He has been featured on various publications like thetruthaboutguns, Sofrep & many more. Joseph is also the founder of Gunloading, where he reviews different types of reloading & firearm products available on the market.

Gunloading.com is a participant in the Amazon Associates Program, an affiliate advertising program designed to provide a means for us to earn fees by linking to Amazon.com and affiliated sites.

About Us | Contact Us | Privacy Policy | Amazon Affiliate Disclosure

Copyright © 2022 Gunloading.com All Rights Reserved